Waste Oil Heaters

By Diane M. Calabrese / Published November 2016

Combustion is a powerful thing. Along with the warmth of candles, lanterns, and hearths, burning refuse has been the surest way to reduce populations of rats and other vermin through the millennia. Incineration of waste does even more in the 21st century. Sanitary living spaces and energy-efficiency both derive from waste-to-energy (WTE) electricity generation plants. The United States had 71 WTEs at the end of 2015.

At every scale of activity, there is innovation in dealing with waste. The waste oil heater is a good example and one that ties directly to our industry. “It costs a lot to have waste oil hauled away,” says Pat Wingen, CEO/COB of Aaladin Industries Inc. in Elk Point, SD. Wingen’s company manufactures waste oil heaters for distribution on catalog sites only, and for that reason, he chose to limit his comments.

Wingen reminds us that an application that uses waste oil to heat water instead of interiors still puts the oil to good use. Not everyone lives in a cold climate, but the ability to eliminate waste oil without hauling and without generating indoor heat is important for some.

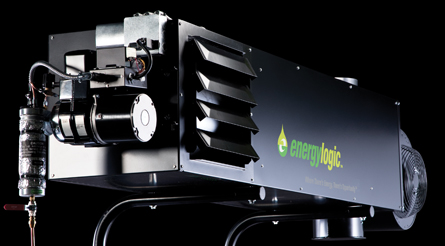

Three individuals in the waste oil heater business approach the issues from slightly different perspectives. Mylan Williams, general manager/sales at Hy-flo Equipment Co. in Pittsburgh, KS, knows directly the intersection between the pressure washer industry and waste oil heaters. Virgil Zook, sales and marketing at Clean Energy Heating Systems LLC in Honey Brook, PA, is a supplier for Williams’ company. Rob Stevens, president/CEO of EnergyLogic in Antioch, TN, leads a company that configures entire systems that integrate waste oil heaters; imagine an auto shop where fans keep warmed air from wall-mounted heaters circulating, with built-in sensors, etc.

Three individuals in the waste oil heater business approach the issues from slightly different perspectives. Mylan Williams, general manager/sales at Hy-flo Equipment Co. in Pittsburgh, KS, knows directly the intersection between the pressure washer industry and waste oil heaters. Virgil Zook, sales and marketing at Clean Energy Heating Systems LLC in Honey Brook, PA, is a supplier for Williams’ company. Rob Stevens, president/CEO of EnergyLogic in Antioch, TN, leads a company that configures entire systems that integrate waste oil heaters; imagine an auto shop where fans keep warmed air from wall-mounted heaters circulating, with built-in sensors, etc.

Cleaner Times (CT): What is most misunderstood about waste oil heaters?

Williams: It’s that they incur a cost There is an initial investment; however, a waste oil heater is one of the few items that you can invest in that pays for itself in a short time and then becomes a profit center for your business. In most cases, a company has a monthly heating cost that can immediately be diverted to investing in a waste oil heater. Once the heater pays for itself, the company’s bottom line will increase.

Zook: “Waste oil heating creates a lot of smoke and soot.” That simply isn’t true. Waste oil heating does not create more dirt or pollution than furnaces that burn #2 heating oil. We design our company’s waste oil furnaces to burn exceptionally clean so they have minimal impact on the environment and require minimal cleanout.

Stevens: A lot of buyers don’t know what to value in their system. People do not emphasize full configuration. We have put a lot of thought into managing the entire system, delivering heat reliably…

CT: Is there an ideal setting for a waste oil heater?

CT: Is there an ideal setting for a waste oil heater?

Williams: It’s any setting where you generate or have good access to a significant amount of used crankcase oil, used automatic transmission fluid, #2 fuel oil or diesel fuel, or used hydraulic oil.

Zook: Waste oil heating is designed for anyone generating 500-plus gallons of used motor oil per year. Because you’re recycling, waste oil heating places less demand on the earth’s valuable resources. In addition, you won’t have to worry about whether or not you’re disposing of your waste oil according to government regulations. With no need to transport your waste oil off-site, you avoid the risks that come with cradle-to-grave liability when hiring a third party to get rid of your used oil.

Waste oil heating is a great way to insulate your business from the volatility of energy prices, particularly oil price hikes. With less reliance on buying #2 heating oil, you can control your heating costs and enjoy more predictable expenses.

Waste oil heating also gives you flexibility. You can burn a variety of fuel options… If you don’t produce enough waste oil on your own, you can buy it from a broker or you can use traditional #2 heating oil in your waste-oil furnace.

Stevens: Any site generating used oil…Heaters from EnergyLogic run on fuels from 5 to 90 weight, including synthetics.

Stevens: Any site generating used oil…Heaters from EnergyLogic run on fuels from 5 to 90 weight, including synthetics.

CT: What’s the most unique/innovative setting in which you have seen a waste oil heater deployed?

Williams: One of our customers uses waterjets for cutting metal. This process requires a cutting oil which they separate from the water and burn in a waste oil heater. They burn this cutting oil year around and literally direct the heat outside and do not utilize it for heating any building.

Stevens: The boiler itself… Features engineered into the system from our company include self-diagnostics and sensors that assess ambient conditions in order to reset temperature and conserve fuel. An option can even be built in that allows the boiler to be used to heat hot water for kitchens, restrooms, and carwashes.

CT: What’s the key to proper maintenance?

Williams: Not allowing significant ash build up in a waste oil heater. Although our supplier has designed a stainless steel heat exchanger and combustion chamber that does not require cleaning more than every 1000-plus hours, it is recommended that the buildup of ash be kept to a minimum to acquire maximum efficiency… Any effort made to keep water, antifreeze, and metal shavings out of the used oil supply tank is another key to properly maintaining a waste oil heater.

Zook: Spring is a great time to give your waste oil heater a thorough cleaning. Clearing out ash, cleaning the burner, and performing other maintenance items are essential for safe operation year-round… Follow the manufacturer’s instructions.

Zook: Spring is a great time to give your waste oil heater a thorough cleaning. Clearing out ash, cleaning the burner, and performing other maintenance items are essential for safe operation year-round… Follow the manufacturer’s instructions.

When your furnace will be offline, turn off the main power to the furnace. Not doing so could lead to oil temperature being maintained over a long period of time without a call for heat. The nozzle adapter heater block may start to accumulate carbon build-up, which could lead to a plugged nozzle.

Stevens: Every equipment needs maintenance. Quick response is key. Quality equipment requires less maintenance.

CT: Is there a waste oil heater improvement that you would like to see in the future, or an improvement that you have been involved in implementing in the past?

Williams: Our supplier has accomplished the improvements we were looking for in the stainless steel heat exchanger/combustion chamber and easy access to them.

Zook: We have implemented vertical flue tubes for minimal ash and residue buildup. We’ve designed our waste oil heaters this way so ash falls neatly into a collection pan. Over-center latches on all clean-out doors make our units very easy and quick to clean. Stainless steel construction and components make our units durable and rust-resistant…High velocity, air-swept heat exchangers mean the hot air produced by our waste oil heaters isn’t only blown around the hot flue tubes, it’s directed onto the entire combustion chambers. That yields more heat, more effective heat transfer—and it more efficiently heats facilities of all sizes.

Stevens: By integrating accessories, the system is made much more reliable. Our company partners with other companies to find the best components to configure entire systems. The systems can be configured with integrated fans, wireless technology for ease-of-access to control of systems, LCD displays, and ease of operation tools, such as a low fuel indicator so that the heater does not run out of fuel (thus requiring it to be primed again).

CT: What should we have asked about waste oil heaters?

Zook: With cleanup and disposal control of waste oil the responsibility of a business, you must make sure the waste is handled it in a way that’s compliant with federal regulations…

You can dispose of waste oil in different ways, including paying an authorized third party to haul it from your site and dispose of it. But, you need to be sure the contract hauler is following all the rules and properly handling the used oil because you’re still ultimately responsible for safe management of the oil you’ve generated—even when the disposal is essentially out of your control.

By investing in a waste oil furnace and burning your used oil as fuel, you’ll have the peace of mind that you’re complying with the federal government’s rules. When you burn waste oil on site, you don’t have to rely on a third party to dispose of it properly, nor do you run the risks of improperly disposing of it on your own.

Not only that, you’ll also reap the financial benefits of producing free heat for your facility. That can lead to some big energy savings for your business.

Stevens: One thing that has changed dramatically is the economic landscape. Natural gas prices went down over the last two years. Generators of waste oil are now having to pay to have oil hauled off. Prior to the decline in natural gas prices, firms might have collected waste oil at no cost for extended use or reuse purposes.

Full circle choices: Pay to have waste oil hauled. Pay for a waste oil heater or system, but dispose of waste oil properly.