The Rules for Selling Heaters

By Diane M. Calabrese / Published November 2019

Add comfort. Hasten drying. Warm up machines. Prepare surfaces. There are almost as many reasons that contractors use heaters as there are types of heaters. Does it mean selling heaters is a good idea? Perhaps.

Dultmeier Sales in Omaha, NE, has been selling heaters for 10 years, says Mike Hansen, sales manager-water division at the company. Given the array of heater configurations, how does a distributor decide which types to include in a product line?

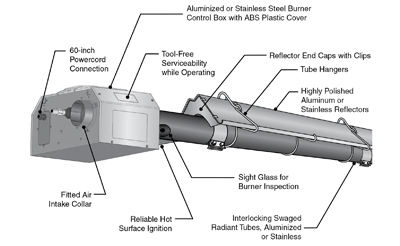

Photo courtesy of Dultmeier Sales. DT Radiant Tube Heater Diagram (c).

Understand the likely needs of your customers. For starters, know the power or source they have available to them. “It depends on the application and location as to if they have natural gas or need propane to run heaters,” says Hansen. Take the time to ask all the correct questions of the buyer. “Always confirm if natural gas or propane is required, as it is hard to change in the field,” says Hansen.

Get as much information as possible from the prospective buyer. A customer arriving with a preset idea may not actually have considered all relevant factors. “We have to size based on what is being heated,” says Hansen. “Is it a wash bay or equipment room? What is the size of the area that needs to be heated? Are we trying to keep floors from freezing, or are we keeping employees or customers warm? Is it a wet environment?”

In the absolute negative category, is there something that tops the list? “Do not undersize,” says Hansen. The type of space in which a contractor will be working will limit the choices. Restrictions on the use of unvented kerosene and natural gas heaters in closed spaces vary by state, but they are growing. Even a covered work area with no walls may not meet the standard for using the combustible gases as a fuel source in an unvented heater.

Another positive for sellers, then, is to know the limitations on types of heaters set by state—and sometimes local—regulators. Kerosene and propane can be used successfully as a fuel source if a heater is properly vented. They must be permanently positioned next to an outside wall to simplify the attachment of the flue gas vent (through the wall to outside or through a ceiling).

Because they require a relatively fixed position, vented heaters pose some limitations for contractors who want to heat more than one work area or move the heater. The alternative to combustible fuel sources on site has long been electricity.

Photo courtesy of Dultmeier Sales. DT Carwash Tunnel Action (c).

“Most heaters for car washes are infrared,” says Hansen. Convection-type electric heaters heat an encased fluid (oil-based) that retains and radiates heat, providing a more-or-less constant heating effect; some designs couple electric heaters with forced air to give warmed air a wider circulation.

While a user does not have to be concerned about noxious gases (i.e., carbon monoxide and nitrogen oxides) with electric heaters, there are still hazards. Tripping over cords, falling heaters, fires, and the like are all in the mix of risks.

Obviously, one thing a seller will want to do is make certain the buyer of a heater understands safe operation. Do remember that often when contractors most need supplemental heat, such as during a prolonged period of freezing temperatures (causing the ambient temperature in a storage

area to drop and machines to get cold), they may be harried and hurried. Particularly at those times, contractors should be encouraged to keep safety as well as heat in mind.

Quality and Service

“Most of our market involves heating buildings—shops, warehouses, etc.,” says Dennis Black, president of McHenry Pressure Cleaning Systems Inc. in Frederick, MD. But not all the buyers have the same context.

“We find two types of buyers for the heaters we sell,” says Black. “One has seen our heaters in operation and/or knows someone who has. The second may have heard of them, but we must demonstrate the benefits of the heater. This sometimes requires a demonstration of the heater, which increases the cost of sales.”

Photo courtesy of Dultmeier Sales. DT Vehicle Storage Action (c).

Black’s company has sold heaters for approximately 15 years. The decision was made to include infrared heaters in the product line because of their singularity and their good performance.

“Infrared was chosen because we wanted to sell something different,” says Black. “Good quality, efficiency, and a type and brand that allows us to build value to the customers” all factored into the decision.

“Selling infrared allows us to maintain the same quality, service, support, and sales margin as our other equipment lines,” explains Black. “Generally, the less a heater costs, the more competition you have. The lower cost heaters are sold by most big box stores and internet companies.”

An absolute must on Black’s list is to add solid performers. “I believe you must pick a type and brand that you can make money on,” he says. “Some heater markets are very competitive and difficult to maintain a good margin on. It is hard to maintain an adequate inventory of heaters and parts if you do not maintain enough profit.”

Black stresses the importance of product support. “Also don’t pick a brand or type where you do not have market and sales support,” he says. “Trying to compete against larger retailers is very difficult.”

Another must on Black’s list is to be sure selling heaters reflects positively on the company. “Offer service, parts, and support,” he says. “The other components of our business—selling pressure washers and more—are based on that. We do not want to sell a product if we cannot maintain the same level of support that we offer on everything else we sell.”

Because the need that a contractor has for a heater may be sporadic, the contractor may be reluctant to own a heater. That’s especially true if different sizes or types of heaters may be needed at different times. And it’s all an opportunity for sellers.

“We have developed a market for rentals of our heaters,” says Black. “This does help us in the market and generates more income from stocking heaters.”

Photo courtesy of J.S. O’Will. Val 6 KBE5k.

Attention to Details

“Initially, we had one or two models, and gradually over the course of time, we have expanded to six main infrared heaters,” says Ken Yoshitake, managing director at J.S. O’Will Inc. in Enumclaw, WA. “In addition to our main line, we also have new products with technology such as ‘far infrared heat’ and also propane- and natural gas-based heaters.”

Yoshitake’s company has been selling VAL6 heaters for close to 20 years. It has an exclusive arrangement to market and sell the brand in the United States, which it does directly and through a network of dealers and distributors

“Our standard line of products is diesel and kerosene-based heaters,” says Yoshitake. “We work closely with our network and manufacturer to assess what is needed by the market.”

“In addition, we also try to be innovative, and as time, environment, and the weather changes, then we try to be adaptive and see how we can best provide products that may be more accommodating to our market and customers,” explains Yoshitake.

Photo courtesy of J.S. O’Will. Val 6 KBE5k.

“Naturally, with some 20 years of sales, we have a lot of loyal customers who know exactly what they want,” says Yoshitake. “But we also have customers who are still relatively new or ask for recommendations based on specific jobs or specific use.”

Yoshitake points to the size of the heater as often being the “biggest” question. A corollary to the question is also common: How many heaters are needed to heat a specific area, such as a warehouse, shop, or garage?

“In general, these are all radiant heaters, and the main function is to provide a comfortable and reliable heat source,” explains Yoshitake. So, size and number of heaters become critical considerations.

There is most definitely a negative to avoid when selling heaters, says Yoshitake. “Do not exaggerate or mislead customers. Our heaters speak for themselves—and a demonstration is the easiest way to show customers heater quality and reliability.”

Yoshitake emphasizes demonstrations as a “must,” as it leads to effective and efficient sales, he explains.

A Must-Have Conservation

The U.S. Department of Energy has several ongoing, multifaceted initiatives to find ways to conserve energy and correspondingly reduce emissions. Since almost one third of the more than 7,000 trillion Btu (TBtu) used by heating systems for U.S. industrial processes annually is wasted (e.g. through poorly maintained equipment), there are multiple reasons to promote efficient heaters to customers.