Cat Pumps

50 Years of an Enduring Mission

By Kathy Danforth / Published April 2018

As Cat Pumps is demonstrating, a long-lasting pump will make a long-lasting company. Founded in January 1968 by William Bruggeman, Cat Pumps is celebrating its 50th anniversary this year. The Minnesota-based company has grown but stays focused on their roots. “Our niche is high quality, long-lasting products,” says current president Steve Bruggeman, son of the company’s founder.

“In 1966, my dad was working for another company, and they put him on a project to design a longer-lasting pump. The pumps at that time were relatively inexpensive and reached 500 psi, but they only lasted 100–200 hours and then were thrown away. They weren’t worth repairing. Self-service car washes often had a 55-gallon drum set out back that they threw pumps in, and then they would dispose of the barrel when it was full.”

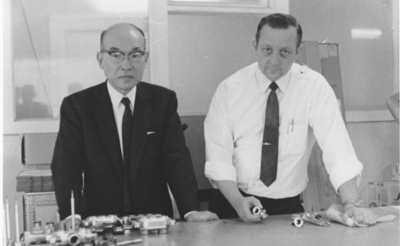

To fulfill his assignment, William Bruggeman developed a triplex piston pump with a uniflow design principle. Steve relates, “They could not find a manufacturer in the U.S. and wound up going to Japan to interview several companies there. On his last appointment, William found a Japanese company that manufactured agricultural spray equipment that used similar manufacturing technologies, and they liked the idea. They worked together and tweaked the prototype until in mid-1967, they had a product completed and tested. Instead of a 100–200-hour life, their prototypes lasted for longer than 2,000 hours. However, the cost was more than 50 percent more than other pumps at the time, so the company said it was too expensive for pressure washers and scrapped the project.”

William Bruggeman, however, saw the benefits and cost savings over time. Steve shares, “He went back to Japan and said, ‘If you manufacture it, I’ll sell it.’ Since he had become friends with the chief engineer there, they built 20 pumps in the model shop. In January 1968, Bruggeman began promoting his new design, mainly to car wash manufacturers, because they had the biggest problem at that time, but some pressure washer manufacturers were also interested because of the long life.

“They rented an old trucking warehouse near the University of Minnesota,” recalls Steve. “The first 100 pumps were delivered in a large crate, and the delivery driver told them to bring over a forklift. Since there was no forklift, they found a couple of pipes and rolled the crates into the warehouse on those.

“Due to the long service life compared to the competition, William called his new company Cat Pumps, which came with the slogan of ‘the pumps with nine lives,’ says Steve. “In addition to having nine lives, they were also thinking of the power of wild cats, like lions and leopards. And, a marketing friend doing research found that company names starting with ‘c’ had a high rate of survival!”

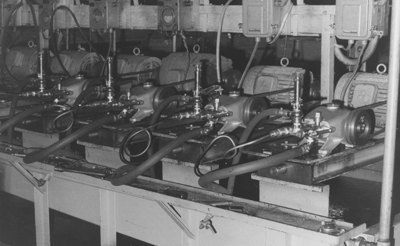

The technology behind these new pumps was a unique piston and valve design. According to Steve, “Most pumps at that time had two pistons, where Cat Pumps were designed with three pistons to decrease pulsation and included a significantly different seal design. Water flowed in between the stationary inlet valve and the floating piston. This cooled and lubricated the cup packing material so it prolonged the life of the pump. Also, the Cat Pump had no external leakage; the two-piston pump was greased and had some leakage between the seal and the wall even from the beginning. We patented that design, and no one has copied it. Five years later, William’s former employer tried to replicate it, but there were flaws in other parts of the pump, so it never had great success. Eventually, that company went bankrupt.”

The original model 400 piston pump was built from 1968–1972. Steve shares, “Just two weeks ago someone who is still using that model called needing repair parts—there are still some model 400s in service that have been used for almost 50 years. That is quite an improvement for those who were throwing a pump away every 30 days.”

With a growing pressure wash and car wash industry in Europe, the company opened a branch in Belgium in 1972. High pressure water also was finding uses in areas such as food processing. “About the same time, the product range was expanding,” according to Steve. “Flows increased from 5 gpm up to 10 gpm, and the maximum pressure rose from 800 psi to 1000 psi.”

In 1976, the forerunner of another major design change was introduced and patented. “Instead of the cup moving, the plunger is moving back and forth with stationary packing,” explains Steve. “That enabled higher pressures up to 3000 psi and revolutionized the industry—more companies started getting into pressure washing.” By this time, Cat Pumps was operating with approximately 20 employees in Minneapolis and another 15 overseas.

In 1978, the company developed a double seal solid ceramic plunger design pump. “That’s the design used in most pressure washers today,” according to Steve. “We changed the sealing mechanism, the material of the plunger, and the way the fluid came in and left the manifold. We developed an exclusive material for the elastomer seal material, but we didn’t patent it because we didn’t want to tell what it was. No one else uses the same material, and it further extends the life compared to our competitors.”

In 1981, the company built a new facility in Blaine, Minnesota, with 106,000 square feet of space. That building was expanded to 149,000 square feet in 1986. Overseas, Cat Pumps has three locations: one in the United Kingdom, one in Germany, and one in Belgium. In addition, “About 15 years ago, we bought another manufacturing facility in the U.K. for larger pumps, primarily serving the petrochemical and desalination industries. Currently, there are about 100 employees here in the U.S. and 75 employees overseas,” Steve reports.

Cat Pumps is still using the same Japanese manufacturing firm that was involved in their launch. “We have stuck with them because of their quality control and attention to detail,” Steve states. “We have virtually zero defects and a warranty rate that is close to zero. Their production engineering standards are so high that we can’t duplicate that anywhere.” In addition, the companies have grown together. “They are in their fourth generation of a family business, and we are in our third,” says Steve.

The technological advances have opened up a new range of flow rates, pressures, and markets. “We have a huge range of products, including more than 1,000 pump models, with flow rates up to 240 gpm and pressures up to 10,000 psi,” reports Steve.

“While pressure wash and vehicle wash were originally the primary applications for Cat Pumps, in the past 25 years many more industries have seen the value of high-pressure systems,” shares Steve. “The benefits of better results with the use of fewer resources (water, labor, chemicals) have opened the doors to a wide variety of applications worldwide.”

A sampling of these many applications where Cat Pumps products can be found include desalination of sea water by reverse osmosis, mist cooling for everything from computer server rooms to gas turbines in power generation, hydro excavation for digging holes for utilities, central cleaning systems in food processing and manufacturing, floorcare/carpet cleaning with high-pressure extractors, and a wide variety of oil and gas process applications.

A big factor in selecting a high-pressure pump or systems is dependability. Steve notes, “One common element cutting across all these applications is the need to get the job done on time with good results.” That’s why Cat Pumps, from the start, adopted a design philosophy that emphasized life and performance over other factors, such as the use of inferior materials to reduce costs. “In the long-run, a better built pump or system reduces costs by keeping equipment running,” observes Steve.

“We are not trying to be all things to all people,” Steve states. “A pressure washer for a homeowner might only last 50 hours, and that may be all he needs. We don’t compete in the low-end market, even though there might be a large volume of sales, because we’re not willing to put our name on a product that doesn’t have exceptional service life.”

“There are cheaper pumps out there,” Steve acknowledges, “but we use what we believe is the world’s best manufacturing company in terms of quality and quality control, and we designed and developed the technology and component materials so that our pumps last longer. It’s the mission of Cat Pumps to manufacture the longest-lasting, most dependable high-pressure pumps possible and back them up with outstanding service and availability from stock.” To date, Cat Pumps celebrates 50 years of mission accomplished and still in progress!