Accessories

Much More than Secondary Players

By Diane M. Calabrese / Published April 2019

A

ccessories guide optional? Subordinate? Mere Nicety?

None of the above.

Accessories are much more than secondary players. They may serve the function of a bigger component by working in tandem with it, adding to its repertoire, or amplifying its power, but they are novel and innovative tools in their own right.

Like core machines, accessories change to keep pace with new needs—so much so that core machines may be changed to make them a better match to the accessories tied to them.

“The Flipper” rotational cleaner.

Tools all, accessories receive the same sort of appraisal from contractors that core machines do. Will an accessory enhance speed and quality? How often will the accessory be used? Is there one accessory every contractor should own? Perhaps, although even the recommendation would be different at different times.

“In my view, the turbo nozzle was the best development of the 1990s, and many contractors have now been using them for decades for specific applications,” says Jeff Theis, president of ProPulse—a Schieffer Co., located in Peosta, IA. “In the modern day, the indispensable item must be the flat surface cleaner, which is probably as impactful to labor savings and efficiency as the turbo nozzle.”

A manufacturer of hydraulic and high-pressure hoses, including a thermoplastic hose that is 100 percent manufactured in the Hawkeye State, Theis’ company offers a product line that is as necessary as it is ubiquitous. But hoses fit into the accessories category, and as reliable as they are in 2019, they should not be taken for granted.

“Of course, as a hose manufacturer, probably the most important accessory every contractor should own is a backup hose,” says Theis. “As mundane as it is, keeping an extra hose or two on the rig will be a major downtime saver as hoses get damaged or worn over time.”

Responsiveness to original equipment manufacturers (OEMs), distributors, and contractors drives development of accessories. Prototype hose assemblies needed by OEMs to move projects forward are supplied quickly by Theis’ company.

Ever-changing

At Hydra-Flex Inc. in Eagan, MN, a contractor spurred the development of an accessory recently added to the roster. “Our newest accessory is Aqua-Rocket, a turbo nozzle designed specifically for industrial cleaning applications,” says Mike Tonies, industrial sales manager at the company.

How did it all happen? “We engineered this product for the contractor who is looking to get longer life out of their tools as well as a better cleaning performance,” says Tonies. “We’ve heard great feedback so far and are looking to continue to find ways to improve how the job gets

done for contractors.”

The continuous improvement and innovation in accessories are informed not only by discussion with contractors, distributors, and OEMs, but also by the context of manufacturers that serve our industry. Manufacturers often serve many industries. Tonies’ company makes products for vehicle washing, hydro-excavation, and industrial cleaning, for example.

Refinement (or re-design) of accessories counts as a big way (and perhaps least-acknowledged way) to reduce carbon emissions. While many think about the machines themselves or their Tier IV engines, innovation in accessories is just as important. The nozzle Tonies mentions not only allows for a job to be completed faster but also uses less water and fuel in the process.

Ease of Use

Improvements in existing accessories and new accessories speed up projects in multiple ways. One of those ways is ease of use.

“We have a new rotational cleaner that operates as a three-in-one tool, providing the user total versatility,” says Scott Myers, product development manager at Barens Inc. in Seneca, PA. “This product has been dubbed ‘The Flipper,’ as it can go from surface cleaner to undercarriage cleaner by simply flip-ping the unit over—no tools needed.”

The underside of “The Flipper” for undercarriage cleaning.

Myers explains that the rotational cleaner “comes complete with Mosmatic swivel, ST 1500 spray gun, and safety shield to assist in protecting rotary arms and swivel” and that it “can be used as a wheeled surface cleaner, floating surface, or under-carriage cleaner.”

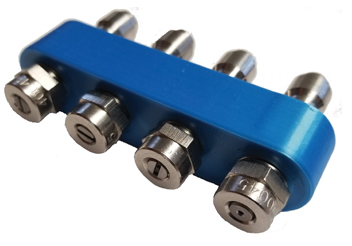

In January 2019, Myers’ company introduced its newest accessory, the Hurricane Quad Coupler—an accessory it manufactures in the United States. “The Quad Coupler holds four individual one-quarter-inch quick-connect female plugs and is made of an elastic polymer,” he explains. “Users may load four spray nozzles of their choice into each coupler.” Free of welds, the coupler includes features such as removable/replaceable plugs that come in four colors (blue, red, green, and yellow).

Scott says that the re-design (including relocation down the frame base) of the reel mount on his company’s Hurricane pressure washers gives it better function and stability—and some nice additional plusses. “Our mounts include precut holes to be used for holders for most turbo nozzles,” he explains. The mounts fit gas and electric models. The company added a mount for its new belt-drive pressure washer.

“We’ve added some nice features to our new aluminum frames, but our favorite feature is that they accept our new optional hose reel mount,” says Myers. The mount can be installed during the initial build or purchased separately for existing pressure washers or frames. “The mounts will accept both 50-foot and 100-foot General Pump-style hose reels.”

Exact Match

Good communication among members of the industry fuels innova-tion. “I encourage every contractor to look at what they have in their hands and study how to improve it,” says Ben Hagemann, general manager at Amer-ican Pressure Inc. in Robbinsdale, MN.

“Maybe the best accessory for any contractor is a good dealer with product knowledge and access to the right products for the situation,” says Hagemann. He recommends that contractors “visit a local CETA dealer, talk over struggles, opportunities, and challenges,” and learn about the array of available accessories.

[Hagemann expresses strong concern that contractors are sometimes tempted to do things with accessories that they should not be doing. He suggests one way to prevent such unsafe practices is for contractors to work closely with a CETA distributor and be sure they are using the correct tool in the way it is intended to be used.]

Hurricane Quad couplers (shown with QC plugs and nozzles for illustration purposes, not included).

“There is no magic bullet for every contractor,” says Hagemann. “They need to understand their applications, people, and process, and work to

make them function more effectively and efficiently.”

Are there accessories that every contractor should own? “Easy pull or relaxed trigger guns are a great place to start,” says Hagemann. “With a little investment in a quality trigger gun, the fatigue of the user goes down, and productivity and quality will rise. Rotating nozzles, flat surface cleaners, hose reels, and telescoping lances are well known by most and have a place in most operations.”

New injector technology to accommodate experienced contractors who want to use a bit more pressure to inject chemicals for certain appli-cations is being offered by Hagemann’s company. “We have come out with our own line of injectors to accomplish that task and can inject at pressures about half the operating pressure,” he explains.

Hagemann provides an illustration of the injector technology: “On a five gpm at 3500 psi machine, we draw chemical effectively at 1750 psi. One other great feature we designed this injector series to help with is extra-long runs of hose or piping. Since we can inject with high back pressure, we will still effectively work with long lengths of hose or other obstructions.”

Ergonomics

Efficiency, emissions reductions, ease of use—the “E”xcellent outcomes of manufacturers and distributors committed to putting the best accessories in hands of end users is already a substantial one. Nevertheless, add to it ergonomics.

“The newest accessory to our product roster is the Kärcher North America Easy!Force Trigger Gun,” says David White, product manager—aftermarket parts at the company in Denver, CO. “This gun has the trigger on the back of the handle, so the pressure of the machine actually helps you hold the trigger gun. This ergonomic design reduces the force needed to hold the gun to zero. This gun comes with a standard three-eighth-inch FPT inlet and one-quarter-inch FPT outlet.”

Surface cleaners are mentioned often as a must-have for contractors. White emphasizes the benefits of surface cleaners by reminding us of their ergonomic value.

“Every contractor should own a quality surface cleaner like our A+ Surface Cleaner,” he says. “It is available in a 21-inch model and a 24-inch model to clean driveways, sidewalks, and patio or pool areas. The surface cleaner will save the contractor time in cleaning these surfaces and also eliminates zebra-striping effect caused by pressure washer wands. Additionally, it cuts down on user fatigue.”

Manufacturers and distributors wish many special products on their extensive lists of accessories had consistently high visibility so contractors could make the best choices for their needs. The A+ Foam Jet Kit is one on his company’s roster that deserves to be better known, says White.

“The kit is rated up to 5000 psi and up to 5.6 gpm,” explains White. “It has a variable spray pattern to help the user get adequate coverage of the detergent being applied. It has a one-quarter-inch inlet and comes with 33 feet of tubing with a chemical filter.”

Environment

Add another important “E” to the list of excellent outcomes refinement in accessories brings, especially in the context of meeting the expectations of environmental (and other) regulators. Verifying coverage of surfaces with cleaning agents is made easier with foam.

Suttner America in Dubuque, IA, recently launched a foam product line in addition to other offerings. “We have a lot of new items we are pretty excited about,” says Jim Shepherd, general manager at the company. “We have a professional sand blaster, new inline spray gun, one-half-inch turbo nozzles, and a universal foam kit. This kit contains an injector and foam nozzle, which makes foaming easy.”

Customer demand sparked the development of the foam product line at Shepherd’s company. Livestock producers in Europe have embraced foam for its effectiveness and efficiency as well as its economy. Foam enhances the even dispersion of chemicals, resulting in a significant drop in the amount of chemical applied.

Shepherd would like to see more contractors adopt foaming after they learn its advantages. “Foaming is becoming more popular in cleaning because it saves time and money on cleaning projects, so contractors should be set up with an injector and foam nozzle,” he explains.

With ability to clean using foam, a contractor can better serve customers that must meet strict requirements for cleaning established by the EPA, USDA, and FDA, as well as OSHA. Foam adds to worker safety (OSHA’s domain) because it can be seen on application and operators applying it use less chemical.

“The one item that is constantly in the contractor’s hand during pressure washing is a spray gun,” says Shepherd. “A good quality, easy to open, ergo-nomic spray gun is essential to reducing fatigue. This gives the contractor the ability to either clean more or reduce the time it takes to clean.”

Excellence

“We drive our long-term product development strategy based on ongoing feedback from both contractors and distributors in the field,” says Bruce Tassone, president of HydraMotion Cleaning Systems in Bridgeport, PA. “We had ongoing feedback on improved chemical management and handling. So, our newest accessory from that feedback is a broad line of transfer pumps that we sell under our FloRite brand. The transfer pumps are designed with materials that are compatible with virtually any and every chemical raw material a contract cleaner would use.”

Can an accessory help a contractor make more money? That’s the enduring question for most contractors, says Tassone.

“Without any debate, every contract cleaner should own a flat surface cleaner,” says Tassone. “It is indis-pensable for use over the vast majority of a contractor’s billable work. We truly believe it is the best accessory available because it is the result of ongoing feedback from users in the field.”

Tassone cites his company’s SideWinder flat surface cleaner as a time saver for contractors. “Not only does it yield the best cleaning results, it has the most robust design which eliminates costly downtime and trips to the dealer for repairs,” he says.

“In recent years, the size of pressure washers is slowly increasing,” says Tassone. “So, we have larger units in our development pipeline that offer the same technical improvements and superior performance as the SideWinder.”

Tassone explains that “feedback and insight” obtained from contractors help his company “tweak” its existing product line. One example? “We found that foaming guns im-proved our application efficiency when using our specialty detergents.”

Summing it up well for all who provide accessories to contractors, Tassone says there is one goal: “Make every contractor task efficient, effective, and repeatable.”